When it comes to oil-fired heating systems, safety is paramount. One of the most important safety devices installed on these systems is the Capillary Fire Valve (TFV), a small yet critical component designed to prevent catastrophic oil fires. In this post, we’ll explain how Capillary Fire Valves work, where they should be placed, and why choosing the correct temperature rating is crucial for effective protection.

What is a Capillary Fire Valve?

A Capillary Fire Valve is an automatic safety device used in oil-fired heating systems to shut off the fuel supply in the event of a fire. This valve consists of a vacuum-sealed capillary tube connected to a bellows system, which is in turn linked to the fuel supply line. The key function of the TFV is to isolate the fuel supply if a fire occurs near the appliance, cutting off the flow of oil to prevent further escalation of the fire.

Here’s a breakdown of how it works:

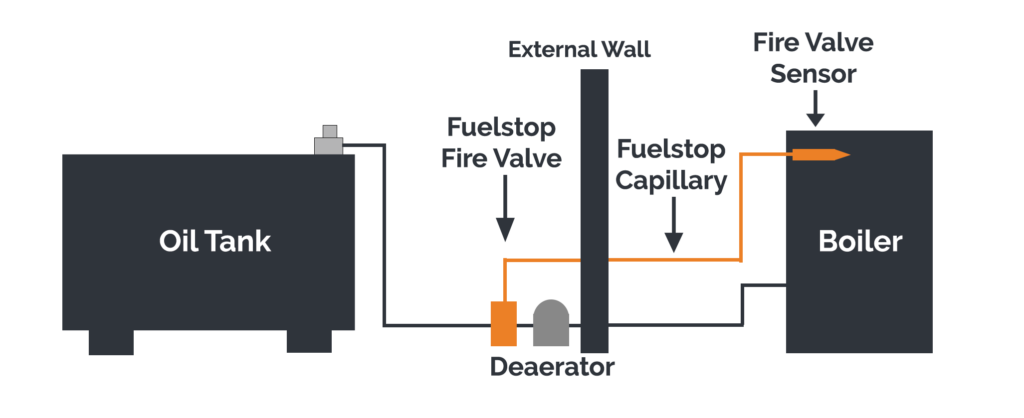

- Location: The probe (or the temperature-sensitive component) is installed near the appliance, such as a boiler, while the fire valve itself is installed outside the building. This setup ensures that the oil supply is shut off before it enters the building, minimizing the risk of oil feeding into a fire and protecting the interior of the building.

- Capillary Tube: This tube acts as a heat sensor. When exposed to high temperatures (typically caused by a fire), it expands or ruptures, triggering the bellows system.

- Bellows System: The heat expansion in the capillary tube releases the vacuum holding the bellows, allowing them to expand and activate the spring system keeping the fire valve open, the fire valve springs shut immediately isolating the fuel supply.

Why are Capillary Fire Valves Important?

In the unfortunate event of an oil fire, the supply of fuel can rapidly worsen the situation, causing the fire to spread uncontrollably. By isolating the oil flow outside the building, the Capillary Fire Valve creates a critical barrier that prevents the fire from spreading further, particularly into the property. This not only protects the building but also buys valuable time for emergency services to respond.

The placement of the fire valve outside the building also ensures that the non-combustible external wall of the structure becomes a secondary defence, providing a physical obstruction that an oil-fed fire would struggle to breach.

Regulatory Requirements

For safety reasons, it is a regulatory requirement that every oil heating system must have a fire valve installed. This is not just a recommendation but a strict rule to protect lives and property.

Temperature Ratings: 72°C vs 95°C

Capillary Fire Valves come with two standard temperature ratings:

- 65-72°C (162°F)

- 72-95°C (203°F)

Understanding when to use each is vital:

-

65-72°C Valve: Ideal for installations where the probe is positioned farther from the burner or in a relatively cool environment. It is more sensitive and will trip if the temperature exceeds 72°C, offering quick response in the event of a fire. However, if the probe is too close to the burner or located in a warm environment, this temperature threshold could result in false alarms—shutting off the fuel supply without an actual fire.

-

72-95°C Valve: This option is suitable for installations where the probe is closer to the burner or in a generally warmer location. The higher temperature threshold prevents unnecessary shut-offs due to ambient heat, making it more appropriate for environments with higher baseline temperatures.

Choosing the Right Valve: Installer Discretion

While the standard temperature ratings are helpful, there is no strict rule about when to use the 72°C vs. the 95°C valve. It often comes down to the installer’s judgment based on factors such as:

- Distance from the heat source (burner)

- Ambient temperature of the environment

- Location of the probe in relation to the appliance

Ultimately, the goal is to balance sensitivity and reliability: ensuring the Capillary Fire Valve will trigger in the event of a fire but not cause unnecessary fuel shut-offs.

The Capillary Valves have a lpm as follows below:

Where Are Capillary Fire Valves Typically Used?

Capillary Fire Valves are most commonly used in domestic oil-fired heating systems. In smaller-scale settings, they provide adequate protection without the need for more robust solutions, like drop-weight fire valves, which are typically used in industrial environments. For residential applications, the Capillary Fire Valves offers sufficient pressure isolation for the smaller pipe diameters and flow rates encountered.

In contrast, drop-weight fire valves are manually operated and preferred in industrial setups, where fuel pressure and flow rates are significantly higher. These heavy-duty valves ensure complete isolation of high-pressure flows, which is essential in settings where an FVC might not provide the necessary force to halt oil movement.

Capillary Fire Valves are only available up to 35 metres, otherwise it becomes too taxing on the gas to travel

Other Relevant Information Regarding Fuelstop Capillary Thermostatic Fire Valves (TFVs)

When selecting and installing Capillary Fire Valves, it’s important to consider several technical specifications that ensure the device will function properly and meet safety standards. Below, we’ll cover additional important details such as connection sizes, capillary lengths, flow rates, and certification, providing a comprehensive guide for installers and users alike.

Fuelstop Fire Valve Connection Sizes

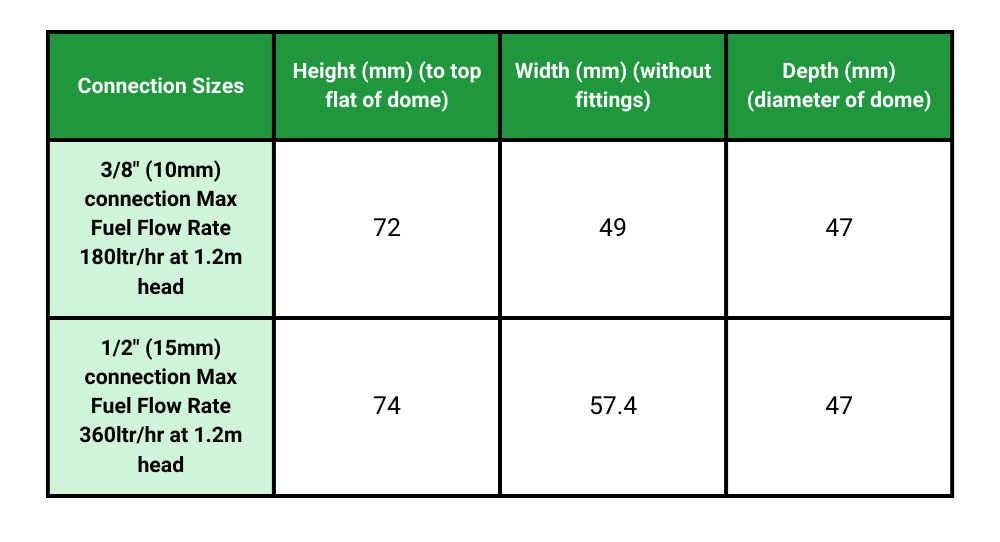

Fuelstop Thermostatic Fire Valves (TFVs) are available in two standard connection sizes:

- 3/8” BSP Female (comes with 10mm compression nut/olive + 10mm insert support)

- 1/2” BSP Female

These sizes are designed to accommodate common piping diameters in domestic and small-scale industrial oil heating systems. Ensuring that the fire valve is the correct size for the system’s piping is essential for maintaining proper flow and preventing leaks.

Temperature Ranges

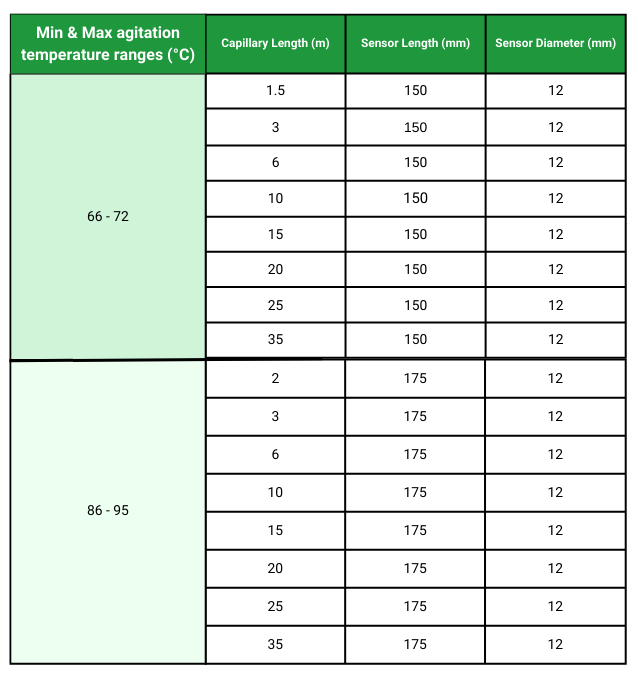

The temperature ranges for TFVs are broken down into:

- 66°C to 72°C (for installations requiring a lower threshold)

- 86°C to 95°C (for higher threshold setups)

These ranges provide installers the flexibility to select a valve based on the operating environment. The upper limits (72°C and 95°C) indicate the point at which the valve will trip, isolating the fuel supply. The specific temperature range of the capillary is determined by the capillary’s manufacturer and will vary slightly depending on the specific device.

Thermostatic Fire Valve (TFV) Flow Rates

The flow rate of a TFV is another crucial factor to consider, especially in systems with suction lift or higher flow demands.

The 3/8″(c/w 10mm compression and inserts) TFV valves are rated at 180 litres per hour (L/hr) with 1.2m head(the vertical distance the oil must be lifted above the valve). The 1/2″ TFV valves are rated at 360 liters per hour (L/hr) at a 1.2m head. This makes them suitable for both suction lift applications and systems with low to moderately high gravity-fed flow requirements.

Thermostatic Fire Valve (TFV) Pressure Rating

TFVs are versatile and suitable for use in both suction and gravity-fed fuel systems. They can handle a range of pressures:

- –0.8 bar vacuum for suction-based systems

- 3 bar positive head for gravity-fed systems

This flexibility makes them ideal for domestic applications, where fuel may be stored below the appliance in a tank, requiring suction to draw the oil to the burner, or above, where gravity assists in fuel flow.

Capillary Lengths

Fuelstop TFV come with a range of capillary lengths to suit different installation requirements. The length of the capillary determines how far the temperature-sensing probe can be placed from the fire valve and burner:

- 1.5m (72°C only)

- 2.0m (95°C only)

- 3.0m, 6.0m, 10.0m, 12.0m, 15.0m, 25.0m & 35.0m

Longer capillary lengths are particularly useful when there is a significant distance between the burner and the valve’s ideal placement, allowing for flexibility in installation without compromising safety.

TFV Accessories

To enhance their functionality, TFVs can be equipped with several accessories:

- TFV Support Brackets: Designed for secure wall mounting, these brackets simplify installation and provide stability for the valve.

- Phial Clips: These clips ensure the correct positioning of the sensor phial within the appliance casing, making sure the probe is placed where it can accurately detect dangerous temperatures.

TFV Approvals & Certifications

All TFVs meet rigorous industry standards and have been approved by OFTEC (Oil Firing Technical Association), conforming to the following certifications:

- OFTEC OFS E101:1996: Ensures the product meets specific safety and performance standards for oil-fired heating appliances.

- BS 5410 Part 1, 1997: British Standard covering oil-fired space heating and hot water supply systems.

- European Pressure Equipment Directive: TFVs are categorized under Sound Engineering Practice (SEP), which ensures compliance with Essential Health and Safety Requirements (EHSR).

These certifications guarantee that the Thermostatic Fire Valves meet the highest safety and quality standards, providing peace of mind for homeowners and installers alike.

Fuelstop Fire Valves Reliability

The Fuelstop Fire Valve range is renowned for its exceptional reliability. Designed and manufactured using the latest technology the capillaries are liquid filled rather than the usual gas filled. The Fuelstop valves are 100% tested for each unit to ensure they meet stringent performance standards. This level of quality and technology helps to reduce nuisance trips, where the valve may falsely detect a fire and shut off the fuel supply unnecessarily, as well as other common issues such as mechanical failure. Every TFV is manufactured in the UK, and each valve carries an individual serial number for traceability. This unique identifier allows for the tracking of both the manufacturing process and individual components, ensuring a high level of quality control. In addition, the Fuelstop Valves are manufactured by Atkinson Equipment Ltd who are ISO 9001:2000 accredited, ensuring that the company adheres to internationally recognised quality management standards.

Conclusion: A Vital Component for Oil Heating Safety

Capillary Fire Valves (FVCs) are essential for ensuring the safety of oil-fired heating systems, offering automatic isolation of fuel in the event of a fire. With their range of connection sizes, temperature thresholds, and capillary lengths, TFVs provide flexibility for various installation scenarios. Their high flow rates and compatibility with both suction and gravity systems make them a reliable choice for domestic settings, while their exceptional build quality and rigorous testing ensure reliable performance.

For installers, understanding the various options and specifications—such as connection sizes, capillary lengths, and temperature ratings—ensures that the right TFV is chosen for each unique installation. With their certifications and proven reliability, Fire Valves provide the peace of mind that your oil heating system is protected from potential fire hazards.